A free import export trade leads B2B marketplace since 1996 for manufacturers, suppliers, exporters, importers, buyers, sellers, wholesalers, freight forwarders, shippers, trade shows, exhibits, and export management.

Hello visitor from USA - 31 visiting from

USA - 31 visiting from  19 USA

19 USA  7 Singapore

7 Singapore  2 Germany

2 Germany  1 China

1 China  1 India

1 India  1 UK

1 UK

Hello visitor from

Lag-s200 Ladle Slag Detection System Vibration Type

Posted at: Offers to Sell and Export | Posted on: Tuesday 6 September 2022 3:45 am | Poster last visit: Friday 21 July 2023 |

Product Category: Main

» Industrial Production and Manufacturing Services

» Machinery and transport equipment manufacture

» Manufacture of machinery

» Metallurgical machinery or equipment manufacture services

» Lag-s200 Ladle Slag Detection System Vibration Type

Product Description:

LAG-S200 Ladle Slag Detection System (Vibration Type)

Overview

The continuous casting vibration type

ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection.

The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system.

The meaning of the system

1. Reduce the amount of tundish slag

2. Improve the purity of molten steel

3. Improve the life of the tundish

4. Reduce sliding nozzle erosion

5. Reduce nozzle blockage

6. Increase the number of continuous pouring furnaces

7. Reduce the amount of residual steel in the ladle when high-quality steel is casting

8. Improve the yield of molten steel

9. Improve the quality of continuous casting billets

The Working principle of the system

The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm.

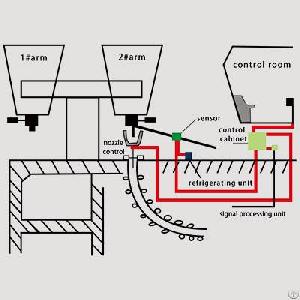

The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle.

The features of the system

(1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise.

(2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times.

(3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life.

(4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm.

(5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction.

(6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance.

(7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag is unloaded, we can choose to automatically close the ladle nozzle or sound and light alarm at the same time, prompting the on-site operator.

(8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day.

(9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish.

Company Contact:

Contact Name: Floria Liang

Company Name: Wuhan Centerrise M&c Engineering Co., Ltd.

Email:

Tel: 13995588597

Fax:

Street Address: Building 4, Hengxin

Industrial Park, No. 8 Xinhua

Avenue, Huangpi District

Wuhan, Hubei 432200

China

Member name: WuhanCenterRise

Country: China

China

Member Since: 06 September 2022

Total Leads: 25 WuhanCenterRise Import Export Business Leads

Business focus: Mold Breakout Prediction System, Ladle Slag Detection System, Mold Expert System, Continuous Casting Billet Detection System, Roll Gap Measuring Instr

Chat:

Verify: Safe Import Export Tips

Overview

The continuous casting vibration type

ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection.

The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system.

The meaning of the system

1. Reduce the amount of tundish slag

2. Improve the purity of molten steel

3. Improve the life of the tundish

4. Reduce sliding nozzle erosion

5. Reduce nozzle blockage

6. Increase the number of continuous pouring furnaces

7. Reduce the amount of residual steel in the ladle when high-quality steel is casting

8. Improve the yield of molten steel

9. Improve the quality of continuous casting billets

The Working principle of the system

The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm.

The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle.

The features of the system

(1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise.

(2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times.

(3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life.

(4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm.

(5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction.

(6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance.

(7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag is unloaded, we can choose to automatically close the ladle nozzle or sound and light alarm at the same time, prompting the on-site operator.

(8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day.

(9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish.

Company Contact:

Contact Name: Floria Liang

Company Name: Wuhan Centerrise M&c Engineering Co., Ltd.

Email:

Tel: 13995588597

Fax:

Street Address: Building 4, Hengxin

Industrial Park, No. 8 Xinhua

Avenue, Huangpi District

Wuhan, Hubei 432200

China

Member name: WuhanCenterRise

Country:

Member Since: 06 September 2022

Total Leads: 25 WuhanCenterRise Import Export Business Leads

Business focus: Mold Breakout Prediction System, Ladle Slag Detection System, Mold Expert System, Continuous Casting Billet Detection System, Roll Gap Measuring Instr

Chat:

Verify: Safe Import Export Tips

Similar Suppliers And Manufacturers Import Export Trade Leads

Similar Suppliers And Manufacturers Import Export Trade Leads

Lag-s100 Ladle Slag Detection System Eddy Current - By WuhanCenterRise - On Tuesday 6 September 2022 3:47 am: ladle slag detection system eddy current

overview

the continuous casting ladle slag detection device is used to detect the slag content of the lad....

Lag-s100 Ladle Slag Detection System Eddy Current - By WuhanCenterRise - On Tuesday 6 September 2022 3:47 am: ladle slag detection system eddy current

overview

the continuous casting ladle slag detection device is used to detect the slag content of the lad.... Lag-s400 Infrared Converter Slag Detection System - By WuhanCenterRise - On Friday 9 September 2022 1:28 am: slag detection system

overview

the infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter....

Lag-s400 Infrared Converter Slag Detection System - By WuhanCenterRise - On Friday 9 September 2022 1:28 am: slag detection system

overview

the infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter.... Ladle Comprehensive Management System - By WuhanCenterRise - On Friday 17 February 2023 8:40 am: ladle integrated management system

overview

in the steelmaking production process the ladle is the key equipment for holding molten steel seconda....

Ladle Comprehensive Management System - By WuhanCenterRise - On Friday 17 February 2023 8:40 am: ladle integrated management system

overview

in the steelmaking production process the ladle is the key equipment for holding molten steel seconda.... S200 Plus Series Continuous Inkjet Printer - By docodgroup - On Tuesday 27 June 2023 7:53 am: s200 plus series continuous inkjet printer

s200 plus printing parameters

machine type

s200 plus cij inkjet printer

print head 1

character lattice

5×6l 7×6l 7×10l 9×8l 9×11l

11×11l 16×16....

S200 Plus Series Continuous Inkjet Printer - By docodgroup - On Tuesday 27 June 2023 7:53 am: s200 plus series continuous inkjet printer

s200 plus printing parameters

machine type

s200 plus cij inkjet printer

print head 1

character lattice

5×6l 7×6l 7×10l 9×8l 9×11l

11×11l 16×16.... Ldt-l200 Ladle Lining Laser Thickness Gauge - By WuhanCenterRise - On Wednesday 7 September 2022 3:49 am: ladle lining laser thickness gauge

overview

ldt-l200 is a new generation of ladle lining thickness gauge launched by our company the system equipme....

Ldt-l200 Ladle Lining Laser Thickness Gauge - By WuhanCenterRise - On Wednesday 7 September 2022 3:49 am: ladle lining laser thickness gauge

overview

ldt-l200 is a new generation of ladle lining thickness gauge launched by our company the system equipme.... Cardan Shaft Universal Joint For Buggy Ladle, Gantry Cranes , Rolling Mills - By ttim - On Saturday 25 March 2023 5:36 am: ladle gantry cranes rolling mills

liquid steel transfer

there are two steps involved in transferring liquid steel from the ladle to the molds fir....

Cardan Shaft Universal Joint For Buggy Ladle, Gantry Cranes , Rolling Mills - By ttim - On Saturday 25 March 2023 5:36 am: ladle gantry cranes rolling mills

liquid steel transfer

there are two steps involved in transferring liquid steel from the ladle to the molds fir.... Precision Slewing Ring Bearing Rks.21 0741 840x634x56 Mm With External Gear For ladle Turrets - By jinshuobearing - On Friday 22 December 2023 12:52 pm: precision slewing ring bearing rks 21 0741 840x634x56 mm with external gear for ladle turrets

precision slewing ring bearing rks 21 0741 840x634x56 mm with external gear for ladle turrets

bearing structure four point contact ball bearing

b....

Precision Slewing Ring Bearing Rks.21 0741 840x634x56 Mm With External Gear For ladle Turrets - By jinshuobearing - On Friday 22 December 2023 12:52 pm: precision slewing ring bearing rks 21 0741 840x634x56 mm with external gear for ladle turrets

precision slewing ring bearing rks 21 0741 840x634x56 mm with external gear for ladle turrets

bearing structure four point contact ball bearing

b.... Coal / Slag / Clinker Vertical Roller Mill Vrm Use Bearing Nnu4192m 760x460x300mm - By lyjhbearing - On Saturday 1 October 2022 6:56 am: slag clinker vertical roller mill vrm use cylindrical roller bearing nnu4192m 760x460x300mm

nnu4192m double row cylindrical roller bearing had matche....

Coal / Slag / Clinker Vertical Roller Mill Vrm Use Bearing Nnu4192m 760x460x300mm - By lyjhbearing - On Saturday 1 October 2022 6:56 am: slag clinker vertical roller mill vrm use cylindrical roller bearing nnu4192m 760x460x300mm

nnu4192m double row cylindrical roller bearing had matche.... Import Export Startup Stories

Import Export Startup Stories

Share Your Story & Get Listed at StartImportExport.com- Ramo Selectronicx: Rahram Palaniyappan Of Ramo Selectronicx In the Business Of Security Electronic Products From India

- Shenzhen Baiteman Tech. Company Limited: Sherry a sales person in Shenzhen Baiteman Tech Company from China

- Beta Packaging Machinery: Anio Lim Of Beta Packaging Machinery From China

- Nanjing Victory Storage Equipment Manufacturing Co Ltd: Jason Of Nanjing Victory Storage Equipment Manufacturing From China

- Global CCTV Security Co Ltd: Julie Zhang Of Global CCTV Security, A Manufacturer Supplier Of Video Surveillance And Security camera Products

Metallurgical machinery or equipment manufacture services Classification Navigation

Metallurgical machinery or equipment manufacture services Classification Navigation

Main - Industrial Production and Manufacturing Services - Machinery and transport equipment manufacture - Manufacture of machinery - Metallurgical machinery or equipment manufacture services [39]

TradersCity.com shall not be held liable for any user posted/submitted content including but not limited to trade leads, profiles, images, and any other data. TradersCity.com does not and did not verify any of users posted/submitted data nor is implicitly or explicitly recommending these business offers. TradersCity does not verify truthfulness, accuracy, completeness, nor legality of any businesses, services, and leads posted here. TradersCity does not represent Sellers or Buyers in any transaction between users of the website and is unable to make any opinion in regard to their performance in any transaction. TradersCity neither guarantees nor undertakes in any dispute between sellers and buyers. Protect your business from fraud by trading safely